Premium PE Outdoor Wall Cladding Systems

Necowood’s high-performance PE wall cladding redefines exterior durability, blending recycled polyethylene resilience with authentic wood-textured finishes for commercial and residential exteriors. Engineered to conquer UV rays, moisture, and temperature swings, these panels deliver a maintenance-free, eco-friendly alternative to traditional siding—ideal for architects seeking weatherproof, aesthetic solutions.

Product Features:

- All-Weather Fortitude:UV-stabilized PE composite shrugs off sun fading (tested to 1,500hr Xenon arc), with waterproof molecular bonding that prevents mold in tropical climates.

- Timber-Look Aesthetics:3D embossed textures replicate oak, walnut, or driftwood without splintering, offering designers authentic natural looks for facades.

- Lightweight Engineering:50% lighter than masonry cladding yet with 28MPa impact resistance, perfect for high-rise installations or retrofit projects.

- Circular Economy Design:Made from 100% post-consumer PE bottles, recyclable at end-of-life, and free of VOCs—LEED v4 certified for green builds.

Product Applications:

- Commercial Facades: Office towers, retail plazas, hospitality resorts .

- Residential Exteriors: Luxury villas, coastal homes, ADU siding.

- Landscape Structures: Pergola walls, outdoor kitchen cladding, pool cabanas.

- Coastal Projects: Beachfront properties, marina buildings, seawall facades3

Why Choose Necowood PE WPC Wall Cladding & Ceiling Panels?

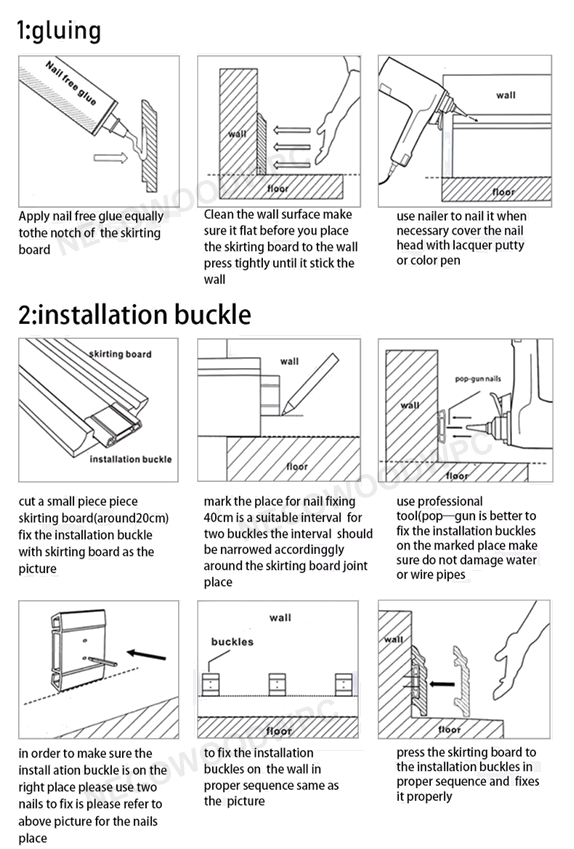

Necowood PE-based WPC panels blend long-lasting durability with natural aesthetics for exterior walls and ceilings, resisting moisture, sun damage, and temperature shifts in commercial and residential projects. Engineered for high strength (38MPa) and light weight, these panels endure impacts and heavy loads without warping, ideal for facades, patio ceilings, and pool areas. Zero upkeep needed—just wipe clean to maintain the finish, cutting costs versus traditional materials. Made from recycled PE and wood fibers, they’re eco-certified and offer custom finishes in various sizes, with quick installation systems proven in global builds.

PE WPC Color Variations for Design Flexibility

Necowood PE WPC Cladding & Ceiling panels offer a diverse color palette, combining weather-resistant durability with customizable finishes for architectural projects. The UV-stabilized hues maintain vibrancy in outdoor applications, suitable for commercial facades, residential exteriors, and renovation work, with bespoke coloring and surface textures available to match design requirements.

Q1: Are PE WPC cladding and ceiling panels eco-friendly?

A1: PE WPC products use 100% recycled polyethylene and wood fibers, with zero formaldehyde or harmful chemicals. They’re fully recyclable at end-of-life, reducing landfill waste—ideal for sustainable commercial and residential projects.

Q2: How does PE WPC withstand outdoor weather compared to traditional materials?

A2: The high-density PE composite resists UV fading (tested to 1,500 hours), moisture damage, and temperature swings (-30℃ to 60℃). Unlike wood, it won’t rot, splinter, or warp in rain or sun, making it suitable for coastal or high-humidity areas.

Q3: What’s the typical lifespan of PE WPC cladding and ceilings?

A3: Outdoor panels last 15–20 years with minimal wear, while indoor applications can exceed 25 years. The cross-linked PE structure maintains structural integrity and color vibrancy over time.

Q4: What materials make up your PE WPC products?

A4: Our formula combines 60% recycled PE, 30% wood fiber, and 10% functional additives for strength and weather resistance. The surface features a UV-stabilized layer for enhanced durability.

Q5: Do PE WPC panels fade in direct sunlight?

A5: UV-stabilizing additives reduce fading by 90%+; third-party tests show less than 5% color change after 10 years of outdoor exposure. Custom colors are formulated for long-term vibrancy.

Q6: What are the standard sizes for PE WPC cladding and ceiling panels?

A6: Standard dimensions are 2900mm length, with widths from 100–300mm. Custom sizes can be arranged for large projects to optimize shipping and installation efficiency.

Q7: Are PE WPC panels fire-resistant?

A7: Panels meet B1 fire rating standards (non-combustible, self-extinguishing), suitable for commercial buildings, public spaces, and residential exteriors requiring fire safety.

Q8: How much maintenance do PE WPC surfaces need?

A8: Minimal—just rinse with water to remove dirt or stains. The non-porous PE surface resists mold, mildew, and chemical damage, eliminating the need for paints or sealants.

Q9: Can PE WPC panels be customized for design projects?

A9: Yes—choose from various wood-grain textures, matte/gloss finishes, or custom colors. Panels can also be cut to curved or angled profiles for unique architectural designs.

Q10: How do PE WPC panels perform in high-traffic or impact-prone areas?

A10: With 38MPa flexural strength, they withstand impacts and heavy loads without cracking. Ideal for commercial facades, retail spaces, or outdoor areas with frequent use.

Q11: What’s the thickness of the UV-protective layer on PE WPC panels?

A11: The UV-stabilized surface layer is 0.2–0.4mm thick, bonded to the core for long-lasting protection against sun damage and weathering.

NecowoodWPC

NecowoodWPC